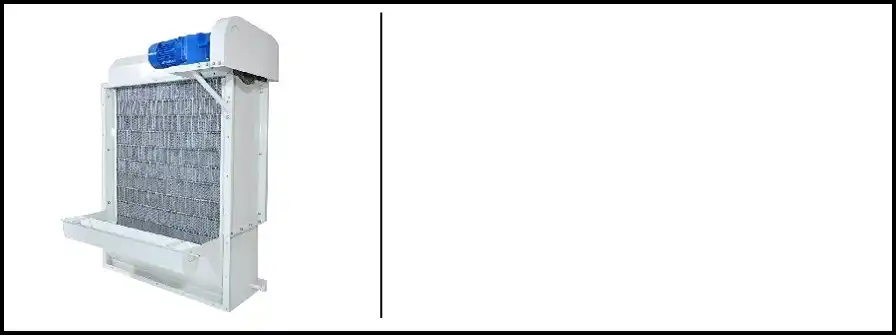

Oil bath / Auto Viscous filter

The self-cleaning viscous air filter or oil bath filters is particularly suitable in many industrial applications to filter large air volumes with high dust concentrations. They are generally used in used in diesel and gas engine applications. It maintains its dust trapping characteristics over an extended period of time and dust will not break away and be carried downstream.

They are one of the most cost-effective technologies to protect your installation from the sand and dust. The time-controlled rotation and the immersion of the panels in the oil tank ensure filter self-cleaning and maintain a constant pressure drop and filtering efficiency. For larger air capacities, single filters can be assembled to form multiple banks. Even in very dusty environment, pressure drop across the viscous surface filter doesn’t exceed 250 Pa

Oil bath self-cleaning filters have numerous advantages: constant cleaning efficiency and pressure drop, minimum maintenance, low operating cost, small footprint and easy installation on site. Moreover, this solution is cheaper than equivalent filter casing with static filter elements or compared to other self-cleaning technologies (pulse-cleaning filters).

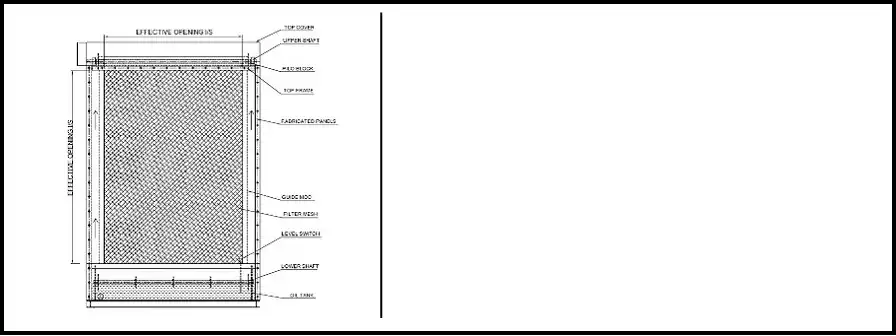

Auto Viscous filter is a self-cleaning viscous filter using a rotating curtain of metal panels as the filtering mat. Behind the filter mat is an endless roll of oil drop eliminator. A timer controlled, totally enclosed thermally protected geared motor rotates the filter media and oil drop eliminator which pass through a viscous oil bath located at the bottom of the filter. The viscous oil cleans the filter media and the oil eliminator minimizes the carry over oil droplets into the air stream. The sludge collected in the oil bath needs to be cleaned periodically.

These filters are especially advantageous wherever dust concentration in the surrounding air is comparatively heavier as in Goal and lignite mines, steel plants, Chemical plants, Cement plants, foundries and other similar Industries.

Filsure rotary panels oil bath filters can be equipped with various components upstream and downstream the rotary panels:

- Inertial dust extraction system.

- Weather louvers and weather hoods.

- Secondary filtration stage.

- Intake plenum, ducting and expansion joints

- Skid approach and skid platform and structure.

Some of the key features and benefits of oil bath filter area:

- Constant high cleaning efficiency and lower pressure drop.

- Minimum maintenance.

- Small footprint and easy installation.

Following are the technical specification of oil bath filter:

- Recommended Air Velocity : less than 3 m/sec.

- Recommended working temp.: 60⁰ C Max.

- Recommended Oil to be used: SAE 30 grade.

- Initial Pressure Drop : 40 Pa

- Final Pressure Drop : 100 Pa

- Rotation frequency : 30 Sec. on 10 min. off

- Motor : 3 Phase. 415 VAC, 50 / 60 Hz

- Filtration efficiency : G2/G3 as per EN 779

For more details please refer oil bath / viscous filter catalogue: